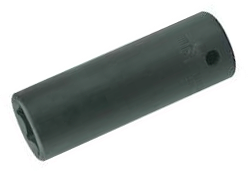

Impact Socket Deep 26MM 1/2″ Drive

£8 Original price was: £8.£7Current price is: £7.

Impact Socket 26mm 1/2″ Drive Deep

Chrome Vanadium

Drop-forged

Six-point

Hardened and tempered for strength

Phosphate Black finish for greater…

100 in stock

You’re now subscribed to price tracking for this product. We’ll notify you if the price drops.

This is a 26mm deep impact socket with a 1/2″ drive, engineered for high-torque applications. It is designed to withstand the repetitive stress and shock loads generated by impact wrenches, making it suitable for heavy-duty fastening and loosening tasks in automotive, industrial, and construction environments.

What You Get

- 26mm socket size

- 1/2″ square drive

- Deep well design for access to recessed fasteners

- Chrome Vanadium steel construction

- Drop-forged for structural integrity

- Six-point configuration for secure fastener engagement

- Hardened and tempered for enhanced strength and durability

- Phosphate Black finish for corrosion resistance and reduced glare

Built For

This impact socket is built for professional tradespeople requiring reliable performance in demanding conditions. It is ideal for:

- Automotive mechanics working on suspension components, engine mounts, and wheel nuts.

- Industrial maintenance technicians dealing with heavy machinery and equipment.

- Construction workers assembling structural elements or disassembling large components.

- Any application where high torque and repetitive impact are standard operating procedures.

Construction

The socket is constructed from robust Chrome Vanadium steel, a material selected for its high tensile strength and resistance to wear. The drop-forging process aligns the grain structure of the steel, further increasing its strength and impact resistance. Post-forging, the socket undergoes a hardening and tempering process to achieve optimal hardness and ductility, preventing brittle failure under extreme loads. The final Phosphate Black finish provides a durable, non-reflective surface that resists rust and corrosion, extending the tool’s lifespan in harsh working environments.