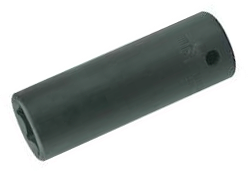

Impact Socket Deep 27MM 1/2″ Drive

£9 Original price was: £9.£8Current price is: £8.

Impact Socket 27mm 1/2″ Drive Deep

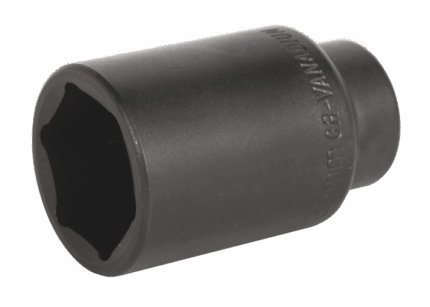

Chrome Vanadium

Drop-forged

Six-point

Hardened and tempered for strength

Phosphate Black finish for greater…

100 in stock

You’re now subscribed to price tracking for this product. We’ll notify you if the price drops.

This 27mm deep impact socket is engineered for demanding fastening and loosening tasks requiring significant torque. It is specifically designed for use with 1/2″ drive impact wrenches and ratchets in professional automotive, industrial, and heavy equipment applications.

What You Get

- 27mm socket size

- 1/2″ square drive

- Deep well design

- Chrome Vanadium steel construction

- Drop-forged for structural integrity

- Six-point (hexagonal) contact for secure grip

- Hardened and tempered for enhanced strength and durability

- Phosphate Black finish for corrosion resistance and reduced glare

Built For

This impact socket is built for high-stress applications such as removing and installing lug nuts, large fasteners on machinery, suspension components, and heavy-duty vehicle maintenance. Its deep well allows access to recessed fasteners and those with extended threads. The six-point design minimizes the risk of rounding off stubborn bolts and nuts, ensuring efficient power transfer from the impact tool to the fastener. Ideal for mechanics, fabricators, and maintenance technicians.

Construction

The socket is constructed from robust Chrome Vanadium steel, a material chosen for its high tensile strength and resistance to wear under repetitive impact. It is drop-forged, a manufacturing process that aligns the grain structure of the steel, increasing its overall strength and impact resistance. The final hardening and tempering process further enhances its resilience against deformation and fracture. The Phosphate Black finish provides a durable, non-reflective surface that resists rust and corrosion in harsh working environments.