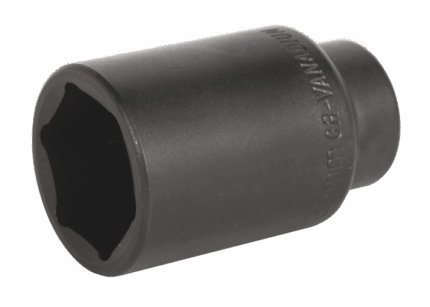

Impact Socket Deep 30MM 1/2″ Drive

£9 Original price was: £9.£8Current price is: £8.

Impact Socket 30mm 1/2″ Drive Deep

Chrome Vanadium

Drop-forged

Six-point

Hardened and tempered for strength

Phosphate Black finish for greater…

100 in stock

You’re now subscribed to price tracking for this product. We’ll notify you if the price drops.

This is a 30mm, 1/2″ drive deep impact socket. It is designed for use with impact wrenches and drivers to apply or remove fasteners requiring a 30mm hex head. Its deep well allows access to nuts on longer studs or in recessed areas where standard sockets cannot reach.

What You Get

- Impact Socket 30mm 1/2″ Drive Deep

- Chrome Vanadium construction

- Drop-forged for structural integrity

- Six-point configuration for secure fastener engagement

- Hardened and tempered for enhanced strength and durability

- Phosphate Black finish for corrosion resistance and reduced glare

Built For

This socket is engineered for demanding applications in automotive repair, heavy machinery maintenance, construction, and industrial assembly. It is suitable for breaking loose stubborn fasteners, torquing critical components, and general high-torque fastening tasks. Its deep profile is particularly useful for axle nuts, suspension components, and other applications where fastener length or surrounding obstructions necessitate extended reach.

Construction

The socket is constructed from a high-strength alloy steel, specifically Chrome Vanadium, as indicated by its specifications. This material choice provides the necessary resilience to withstand the high impact forces generated by power tools without deforming or fracturing. The manufacturing process includes drop-forging, which refines the grain structure of the steel, further improving its strength and impact resistance. Hardening and tempering treatments are applied to achieve optimal hardness for wear resistance and toughness to prevent brittle failure. The matte black finish is a phosphate coating, which offers a degree of corrosion protection and reduces light reflection in working environments.